Submerged Arc Welding (SAW)

You are here

Submerged Arc Welding (SAW) is a very productive process with an electric arc under a layer of powdered flux. The powder forms a slag that protects the weld pool from atmospheric influences In addition, this can affect the mechanical properties of the weld. The power current values can become very high, making use of thick wire possible and extremely high deposition rates can be achieved.

The benefits of submerged arc welding are the high speed, good penetration, no spatter, no radiation, low fumes and prolonged working cycle.

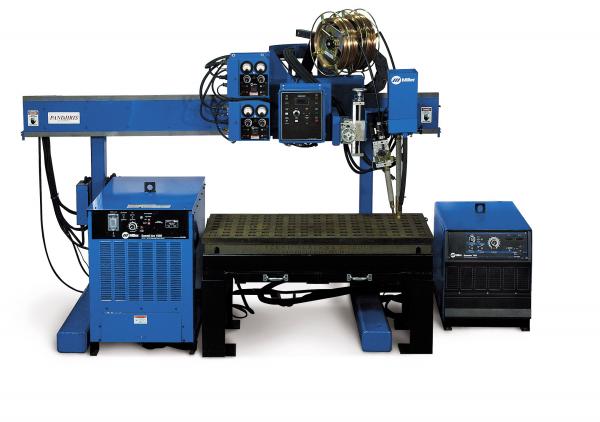

Miller has a complete range of these welders that have already proved their value among our customers.

Our SubArc Digital Series offers both DC and AC/DC capabilities. DC Digital models are rated for 650 – 1000 Amp; and AC/DC Digital models are rated for 1000 amps at 100% duty cycle.

The power sources have the capacity to handle Submerged Arc (SAW) and Electroslag (ESW) welding applications, from traditional DC single-arc to multi-wire tandem welding. In the case of ESW welding or other high-current demand, two or more power sources can easily be paralleled.

In addition to these power source options, the series offers two interface controls — analog and digital — and a range of wire drive motors and accessories, including single- and twin-wire torches, and external cladding heads. The accessories are powered with a safe, low control- voltage (24 VAC) from the power source.