Premium Cutting Machines / 4000 series

You are here

THE ZINSER PREMIUM SERIE

The machines of the ZINSER premium series are known worldwide for their excellent cutting quality.

Whenever an extraordinary machine reliability is required, like in the steel industry, customers have relied on ZINSER premium cutting machines for decades.

The high flexibility and numerous options make ZINSER premium cutting machines the perfect partner for every cutting task. With a large number of tools and additional components, the ZINSER cutting systems can be optimally tailored to any customer‘s requirement.

Your advantages with the ZINSER premium cutting machines

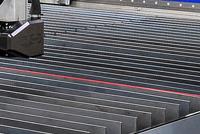

- The extraordinary robust design, linked with a high stiffness, precise linear guides and a heavy duty runway guarantee the very best quality and a long duration of life

- High flexibility and various options

- By use of a wide number of tools and additional components the ZINSER cutting systems match your cutting task perfectly

- Special applications like drilling and thread cutting or oxy-fuel heavy duty cutting are no problem with these machines

- Excellent cutting quality

Basic Scope of delivery

Gantry bridge

- High precision bridge, welded structure, produced according to most modern standards

- Double ball rail systems for torch / tool carriers

Track / Y-Drive

- Bilateral AC servo drive 3 x 400 V

- Perfect running smoothness, high angle accuracy by the use of selected racks and precise planetary gears

- Hardened drive pinions

- Adjustable contact pressure of the drive pinions

Drive Carriage / X-Drive

- AC-servo drive via rack and pinion 3 x 400 V

- Slave carriages are clamped on CrNi steel wire

- Motorized torch height control with 4 quadrant regulator

Options

- SPS-controlled fume extraction tables, cartridge filter systems with pneumatic cleaning

- External CAD / CAM nesting software

- Network link

- Adaptation to customer’s requirements possible anytime

Upgrade components

Oxy-fuel:

- Digital piercing unit with database for plate thickness up to 200 mm

- Electrical ignition unit

- Automatic torch height control

- Automatic torch positioning (for multi-torch use)

- Single or triple torch beveling devices

- Single torch addressing

Plasma:

- CNC controlled data communication to plasma power source with automatic gas console, cutting data is sent directly from the CNC controller to the system (database) with automatic setting

- Arc voltage height control with data connection and automatic communication

- Full or semi-automatic beveling devices

Marking units

- Plasma marking

- Inkjet

- Needle marking

- Drilling unit

- Punching unit

- Powder marking

CNC-Drilling unit

- For holes up to 40 mm diameter (in plate of 100 mm)

- Automatic tool changer for drilling unit

- With broken drill detection device

Machining of pipes and beams (only 4026B / 4126B):

- Cantilever up to 2000 mm

- Rotating axis for pipes up to 1000 mm diameter

Drilling Ø18 mm, 250 mm plate

With the ZINSER 4125B customers can not only achieve excellent plasma and oxy-fuel cuts. Drilling, threading and countersinking operations are also no problem with the ZINSER CNC drilling unit. This video shows the drilling of a hole with a diameter of 18 mm through a 250 mm thick steel plate with a cutting speed of 35 m/mm.

40 mm blind hole / 18 mm through hole

Drilling of a 40 mm blind hole and afterwards in the middle a 18 mm through hole on a ZINSER 4125B. Material: HARDOX® 450

Drilling 40 mm

Drilling 40 mm on a ZINSER 4125B

Tool changer

The tool changer of ZINSER cutting machines has multiple tool positions and can be loaded with drilling, countersinking or threading tools. The ZINSER CNC drilling unit can thus be loaded fully automatically through the CNC controller.

This fully automatic integration of different manufacturing processes significantly increases your workpiece quality and production efficiency.