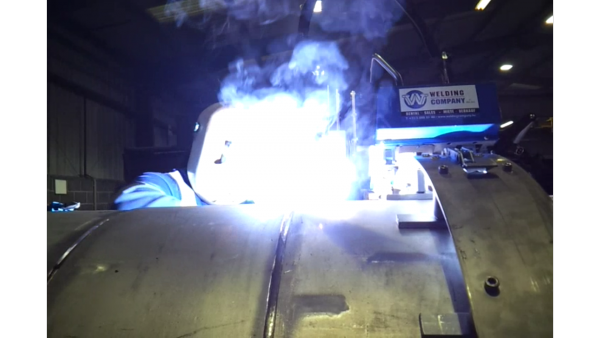

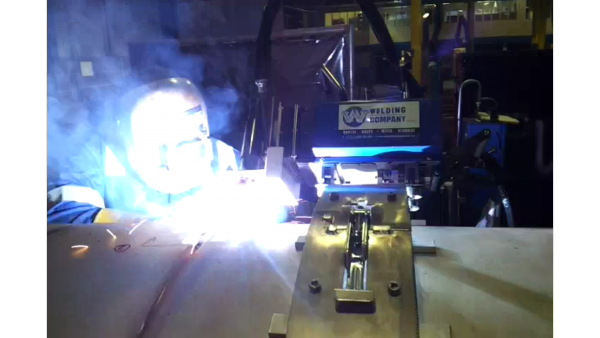

Firefly MIG Welding System

You are here

The firefly, commonly referred to as a ‘welding bug’ or ‘weld head’, is a semi-automatic external welding machine designed and manufactured in the UK by IPWL. The firefly’s unique features combine to give you a smarter welding machine that works with you in the most demanding situations.The firefly is designed to meet the most rigorous standards and is particularly suited to applications requiring a high level of weld repeatability. The purpose of the firefly system is to improve the productivity of the welder by continually producing a consistent weld result. We believe this gives our customers a competitive edge in today’s ever demanding economic climate.

ADAPTABLE SYSTEM

An adaptable system for welding, cutting and bevelling, full of clever features to make your life easier.

AUTOMATED WELDING

A clever welding machine that fulfils your automated welding requirements

FIREFLY FEATURES & BENEFITS

- Firefly incorporates leading digital technology for precise control of key welding parameters.

- Firefly has multiple pass welding capability for workpieces in all gravity positions.

- Firefly has sector control. This feature enables the customisation of specific sectors to give the maximum flexibility and repeatability to weld parameters.

- Firefly has an automatic torch height adjustment feature as standard (with suitable inverters).

- Firefly’s robust design features cope with the most demanding applications and terrain.

- Firefly systems are calibrated to enable all weld procedures to perform exactly the same when using multiple Firefly machines.

- Firefly has a root pass capability without the need for copper or ceramic backing shoes.

- Firefly’s compact size means it can work in confined areas.

- Firefly has both hard wire and flux core welding capability due to the high torque motor installed, effective feed of all types of weld wire is possible.

- Firefly is compatible with suitable inverters from all manufacturers.

- All this combines to give you a clever welding machine that fulfils your automated welding requirements.

INTEGRATED WELD DATA LOGGER

Firefly includes an integrated arc welding data logger and monitoring unit. The unit offers a built in solution – a seamless integration with minimal start up times and no external cabling.

Mounted to the front of the Firefly control box, the eight-inch touch screen unit will monitor variables such as arc voltage, arc current, wire feed speed, travel speed, arc time and traverse speed. Data is captured digitally, direct from the weld power source.

PURPOSE

The purpose of the unit is to aid the decision making process by providing users with information about the actual weld.

- Real time weld monitoring – the unit measures the defined variables to enable the comparison of those variables to upper and lower limits within the weld procedure, then communicates the results of this comparison.

- Weld data acquisition – the unit measures, displays and stores the defined variables to evaluate specific arc characteristics.

- Production data – the unit provides various layers of productivity related information.

The value of the unit comes when the output is compared to the pre-set tolerances for the workpiece.

Armed with real time information, the user can quickly identify potential process variances and take appropriate remedial action to ensure the weld procedure is followed.

KEEPING UP WITH INFORMATION DEMANDS

Weld records are a significant part of the huge amount of documentation required to achieve weld validation.

Firefly's data logger will allow the actual weld data to be exported directly to a computer for compilation of weld records for the job – there is no need to re-enter data manually from reams of printed material.

If printed documentation is required for QA purposes, data can be printed from automatically generated PDF reports.